Processing coffee beans

Before being pocketed, the fruit of the coffee tree should be subject to some prior processing. The main steps include the following:

- Harvesting coffee: When the fruits are ripe, harvesting process starts. Maturity is usually reached in the Arabica species between 6 and 9 months after flowering (about three months later in Robusta species). Harvesting can be done in a manual way, by selecting only the ripe fruit. In this case, it is a process that requires picking it in several times which makes it a slow and expensive process. However, this will produce a very homogeneous and very high quality coffee.

The other possible method of harvest is the stripping. It consists on scraping the branches of coffee, manually or mechanically, to loosen the fruit all at once. This is done to get a crop in which the fruits are fully mature mixed with others that have not yet reached full maturity. This type of harvest has the advantage of being faster and more economically profitable, although it produces coffee with less quality, because the mixture increases the acidity and decreases the aroma and flavor.

- Elimination of the outer layers: After harvesting, the outer layers of coffee seed must be removed, both the pulp layer that protects the seed and the papery layer immediately surrounding the seed. This can be done through two different methods:

- Dry process coffee: Coffee beans are extended in a large area and are subjected to the action of sunlight. This is done to dry the fruit which is then mechanically barked. This method is always used for the treatment of Robusta species, and in some places, for the Arabic, too.

- The wet method: It is a process more often used: It consists on making the fruits ferment in special tanks. The action of microorganisms, such as Bacillus lactis aerogenes, begins a fermentation process of the pulp which becomes softer and is eventually dispersed. Then the fruits are subjected to an intensive washing process and, finally, to a mechanical scraping to remove the pulp.

To remove the parchment layer surrounding the seed a series of reagents are used. They soften the seed and, subsequently, they are subjected to a mechanical cleaning. This process gives a higher quality coffee than the dry method, but it is a highly undesirable process from a standpoint of environmental quality, both by the high water consumption and pollution of water used.

- Sorting and filtering coffee: Whether a method or another, from this process of removing the outer layers green coffee is obtained, then it must be classified according to size of the grains. During this step those grains that are in poor condition or any residues or impurities that were left over from previous processes will be eliminated.

- Polishing coffee: Green coffee is also called “brown film” because each grain is surrounded by a white silvery layer. Coffee grains are polished to removed it.

- Storing and Aging coffee : To accentuate its taste, coffee is stored in fiber bags in a cool dry place for a period ranging from one to three years. This ensures that the coffee ages and presents a more pleasant taste and aroma.

- Decaffeination: Green coffee has a very high caffeine content (about 2%): To avoid its harmful effects, some caffeine must be removed. To make this process possible, the beans undergo a process of hydration and subsequently caffeine is removed by organic solvents or activated charcoal. Another possible process is to apply a jet of CO2 to the seed

The so-called “decaffeinated coffee” is a variety of more exhaustive coffee decaffeination process so that it removes the grain almost all caffeine.

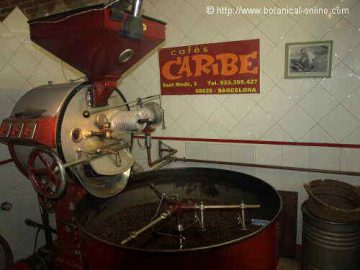

- Toasting: The green coffee is not too pleasant to eat because its too bitter. Before consumption, it should have a roasting process which gives it its peculiar taste and its so characteristic aroma.

Roasting is done in an oven at temperatures between 200 and 250 º C. This process breaks caffetannic- acid which appears to be responsible for its harshness. It is also responsible for the appearance of the essential oil, rich in cafeone, which is what gives its pleasant taste.

Other quite remarkable changes are color change from green to brown, water loss (from 8 to 12% goes to 0.4 or 4%), reduction of caffeine, reduced grain weight and increase in their volume which is going to be a third larger than the green beans.

- Roasting: In the process of roasting coffee sugar is added. Coffee will be caramelized by heat, giving the grain a glossy look and a stronger flavor. This type of coffee is called ” roasted coffee”.

![]() More information about coffee and caffeine.

More information about coffee and caffeine.